As the Canadian manufacturing sector continues to evolve with automation and precision technologies, CNC (Computer Numerical Control) machinists remain integral to industrial operations. From aerospace and automotive to medical devices and heavy equipment, CNC machinists are the skilled backbone that keeps production lines efficient, accurate, and scalable.

But with demand outpacing supply in many regions of Canada, staffing firms are facing growing pressure to source, train, and retain top-tier machinist talent. This article explores the CNC machinist role from a staffing perspective—outlining hiring trends, key qualifications, recruitment challenges, training pipelines, regional demand hotspots, and future workforce strategies. Whether you’re a hiring manager, recruiter, or CNC professional, understanding this labor dynamic is crucial to navigating one of Canada’s most vital skilled trades.

Understanding the CNC Machinist Role

CNC machinists program, operate, and maintain computerized machines that cut, drill, and shape raw materials like metal, plastic, or wood into precise components. These machines follow exact specifications from computer-aided design (CAD) and manufacturing (CAM) software, making machinists essential for industries where precision is non-negotiable.

Core Responsibilities Include:

- Reading and interpreting technical blueprints and CAD files

- Programming CNC machines using G-code or proprietary software

- Setting up tools, fixtures, and materials for production

- Operating machines and monitoring for accuracy or faults

- Performing quality assurance checks and dimensional measurements

- Maintaining, troubleshooting, and repairing machines

Key Soft and Technical Skills:

- Attention to detail and spatial reasoning

- Mechanical aptitude and problem-solving

- Familiarity with inspection tools (micrometers, calipers)

- Knowledge of metal properties and cutting speeds

- Basic math and geometry proficiency

- Safety and regulatory compliance

Current Demand for CNC Machinists in Canada

Across Canada, CNC machinists are listed as in-demand under the National Occupational Classification (NOC 72101). Staffing data reveals growing shortages, particularly in provinces with strong manufacturing hubs such as Ontario, Quebec, British Columbia, and Alberta.

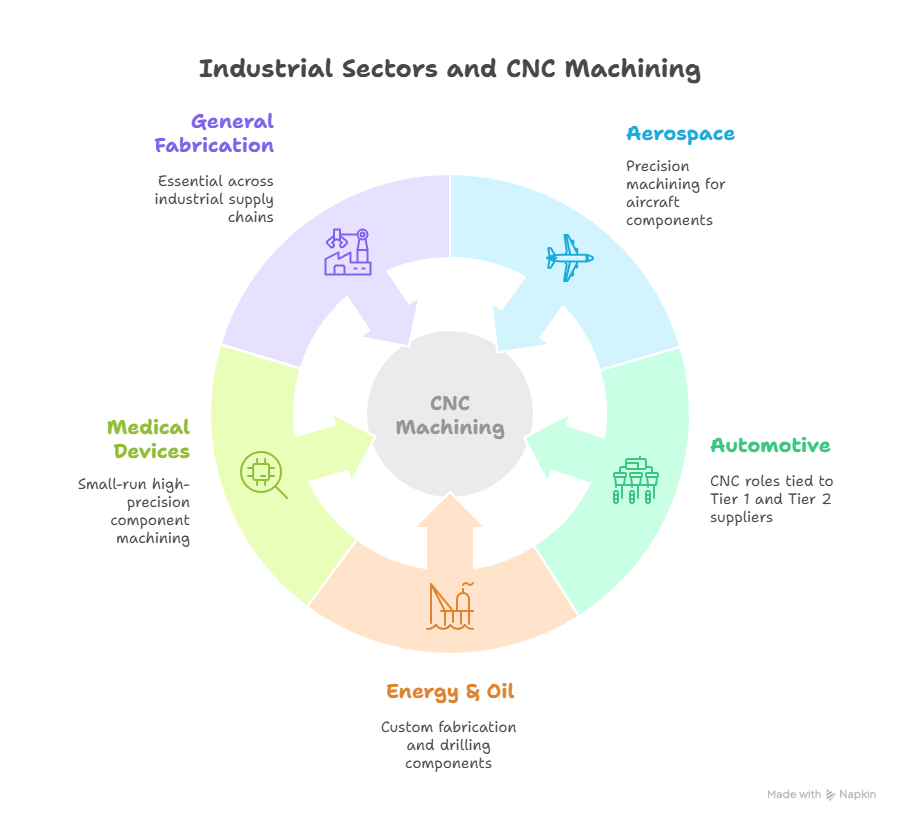

High-Demand Industries

- Aerospace (Montreal, Toronto): Precision machining for aircraft components

- Automotive (Ontario): CNC roles tied to Tier 1 and Tier 2 suppliers

- Energy & Oil (Alberta): Custom fabrication and drilling components

- Medical Devices (Toronto, Vancouver): Small-run high-precision component machining

- General Fabrication & Tool & Die (nationwide): Essential across industrial supply chains

According to industry reports, over 30% of skilled tradespeople in Canada are nearing retirement age, intensifying the need for younger machinists to enter the field.

Staffing Challenges in CNC Recruitment

Despite solid compensation and job security, staffing CNC machinists remains a complex challenge due to several interrelated factors:

1. A Shrinking Skilled Labour Pool

Many youth are opting for university education over trades, leading to a shortage of CNC apprentices and graduates. The skilled trades stigma remains a barrier.

2. Geographic Mismatches

High CNC demand in certain provinces isn’t always matched by available talent. For instance, Alberta may need CNC machinists for oil & gas applications, but candidates may be concentrated in southern Ontario or Quebec.

3. Skills Gaps

Employers increasingly seek machinists with multi-axis CNC experience or familiarity with advanced software and automation—qualifications not always covered by traditional programs.

4. Retention and Poaching

Top machinists are in high demand and often field multiple job offers. Retaining them requires competitive pay, positive workplace culture, and growth opportunities.

5. Lengthy Hiring Timelines

Thorough vetting is essential given the role’s precision requirements. Recruiters must balance speed with due diligence when matching candidates.

Strategies for Staffing Agencies and Employers

To address these challenges, staffing agencies and in-house HR teams are adopting multi-pronged strategies.

1. Investing in Apprenticeship Partnerships

Collaborating with technical colleges and apprenticeship programs helps build a pipeline of junior machinists. Sponsoring or co-developing curriculum based on real-world machine shop needs can also improve graduate readiness.

2. Upskilling Internal Candidates

Offering internal training to general machinists or operators to step into CNC roles is a growing strategy. This can be done via short-term programs, vendor certifications, or mentorship under senior CNC professionals.

3. Flexible Contract Staffing

For companies facing seasonal or project-based surges, staffing firms provide short-term CNC machinists without long-term commitments. This helps fill urgent vacancies or cover medical leaves and vacations.

4. Employer Branding

To attract talent in a competitive market, agencies encourage clients to improve their job descriptions, showcase workplace safety, highlight advanced tech, and offer visible career progression pathways.

5. Immigration and Foreign Credential Programs

With local talent limited, some firms explore international hiring through programs like the Temporary Foreign Worker Program (TFWP) or Provincial Nominee Programs (PNP) tailored for skilled trades.

Regional Spotlight: Where CNC Talent Is Needed Most in Canada

Ontario

- Major cities: Toronto, Windsor, Kitchener-Waterloo, London

- Dominant sectors: Automotive, tool & die, aerospace

- Notes: Government funding for apprenticeship subsidies helps firms invest in long-term recruitment.

Quebec

- Major cities: Montreal, Laval, Quebec City

- Dominant sectors: Aerospace (e.g., Bombardier), medical

- Notes: French language skills may be required in client-facing roles; high concentration of CNC education programs.

British Columbia

- Major cities: Vancouver, Surrey, Kelowna

- Dominant sectors: Shipbuilding, fabrication, tech hardware

- Notes: Increasing demand for CNC machinists with CAD/CAM software fluency.

Alberta

- Major cities: Calgary, Edmonton, Red Deer

- Dominant sectors: Oil & gas, custom fabrication, energy

- Notes: Machinists often need exposure to rugged component machining and extreme tolerances.

Education and Training Pipelines

Canada boasts a robust network of technical colleges and trade schools producing CNC machinists. These programs typically offer diploma or certificate paths that blend theory with hands-on shop time.

Top Training Institutions:

- George Brown College (ON)

- British Columbia Institute of Technology (BC)

- Red River College Polytechnic (MB)

- Centre de formation professionnelle de Verdun (QC)

- Southern Alberta Institute of Technology (SAIT)

Most programs are 1–2 years long, followed by apprenticeships where students accumulate hours toward their Red Seal certification, a recognized interprovincial standard for trades.

Compensation and Career Progression

CNC machinist salaries in Canada vary by region, experience, and industry.

| Experience Level | Average Hourly Rate (CAD) |

| Entry-Level (0–2 yrs) | $20–$26 |

| Mid-Level (3–5 yrs) | $27–$35 |

| Senior (6+ yrs) | $36–$45 |

| Programmers (CNC + CAM) | $38–$50 |

Some experienced machinists transition into:

- CNC programming roles

- Machine shop supervisors

- Tooling engineers

- Quality assurance inspectors

- Technical sales or CAD/CAM trainers

From a staffing perspective, emphasizing these growth paths helps attract candidates who may be seeking long-term development beyond hands-on machining.

Safety, Certifications, and Employer Requirements

CNC machinists work in fast-paced environments that require rigorous adherence to safety protocols. Staffing firms must ensure candidates are equipped with:

- WHMIS training

- Lockout/tagout procedures

- PPE usage compliance

- Knowledge of ISO or AS9100 standards (in aerospace/medical sectors)

For high-stakes industries, additional certifications such as Red Seal Endorsement (RSE) or Canadian Welding Bureau (CWB) qualifications are sometimes mandatory.

The Role of Automation and the Future of CNC Staffing

The rise of Industry 4.0 is transforming CNC operations with technologies like:

- Multi-axis machining centers

- Robotic tool changers

- IoT-enabled diagnostics

- Remote monitoring and predictive maintenance

- AI-assisted CAM software

While automation improves productivity, it also raises the technical bar for machinists. Staffing firms are increasingly tasked with finding CNC talent who are digitally fluent and adaptable to continuous tech evolution.

Some employers are introducing hybrid machinist-programmer roles, blending traditional operation with real-time troubleshooting, code editing, and software control. These roles are highly compensated but scarce in availability, creating both an opportunity and a challenge for recruiters.

Staffing Recommendations for Employers Hiring CNC Machinists

- Audit Internal Training Programs: Align your onboarding and ongoing training with the latest CNC technologies to remain competitive.

- Use Contingent Staffing Strategically: Partner with staffing firms to scale workforce efficiently during growth cycles or large-volume orders.

- Prioritize Retention: Offer apprenticeships, shift flexibility, merit-based raises, and clear paths to leadership.

- Leverage Government Programs: Utilize wage subsidies, hiring grants, and training credits specific to skilled trades.

- Communicate Tech Appeal: Today’s candidates value innovative work environments—highlight your machine shop’s use of modern equipment and digital tools.

Forging Canada’s Industrial Future with a Resilient CNC Workforce

CNC machinists stand as the bedrock of Canada’s advanced manufacturing sector, their expertise indispensable to a diverse range of industries, from aerospace and automotive to medical devices and energy. Their ability to translate digital designs into tangible, high-precision components drives innovation, enhances productivity, and ensures Canada’s competitive edge in the global marketplace.

However, Canada faces a critical juncture. The demographic reality of an aging workforce looms large, with a significant portion of experienced machinists approaching retirement. This exodus of institutional knowledge, coupled with an intensifying global competitive landscape, transforms the task of staffing the next generation of CNC machinists into not merely a recruitment challenge but a strategic imperative for the nation’s economic vitality. It’s a nationwide challenge that demands a concerted, multi-faceted response from all stakeholders.

To bridge this looming skills gap and secure Canada’s industrial future, staffing professionals and employers must pivot towards a future-forward paradigm. This necessitates a proactive and holistic approach that extends beyond traditional recruitment methods. Key strategies include:

- Deepening Alignment with Educational Institutions: Forging stronger, more symbiotic relationships with vocational schools, colleges, and universities is paramount. This involves collaborating on curriculum development to ensure it aligns with industry needs, offering apprenticeships and co-op programs that provide practical, hands-on experience, and investing in state-of-the-art training equipment that mirrors modern manufacturing environments. This proactive engagement will cultivate a pipeline of skilled graduates ready to enter the workforce.

- Modernizing Recruitment Messaging and Branding: The perception of manufacturing careers must evolve. Recruitment campaigns need to highlight the high-tech, innovative, and intellectually stimulating nature of CNC machining, showcasing it as a rewarding career path with opportunities for continuous learning and advancement. Emphasizing the tangible impact of their work and the contribution to national prosperity can attract a new generation of talent.

- Embracing Upskilling and Reskilling Initiatives: Investing in continuous learning for the existing workforce is crucial. As technology advances, machinists need opportunities to upgrade their skills in areas like automation, robotics integration, data analytics, and advanced materials. This not only enhances their capabilities but also boosts morale and retention. For new entrants, comprehensive training programs that combine theoretical knowledge with practical application are essential.

- Strategic Adoption of Smart Automation and AI: Rather than viewing automation as a threat, employers should embrace it as a tool to augment human capabilities. Smart automation can handle repetitive tasks, improve efficiency, and enhance safety, allowing machinists to focus on more complex problem-solving, programming, and quality control. Implementing AI-driven predictive maintenance can also optimize machine performance and reduce downtime, making the workplace more efficient and attractive.

- Fostering a Culture of Support and Mentorship: Creating a supportive work environment where experienced machinists mentor new recruits can significantly accelerate skill development and foster loyalty. Acknowledging and celebrating the contributions of machinists can also boost morale and reinforce the value of their craft.

By strategically integrating robust training initiatives, providing unwavering support for skill development, and exercising astute foresight in anticipating technological shifts and workforce needs, Canada can not only mitigate the current challenges but also proactively cultivate a truly resilient and innovative CNC workforce. This concerted effort will empower the nation to not only sustain its industrial momentum but also to thrive, powering Canada’s industrial future with precision, ingenuity, and a highly skilled workforce.