The Canadian manufacturing sector is undergoing a transformation—driven by advanced technologies, increased demand for lightweight materials, and an ongoing shift toward sustainable production. One critical area experiencing consistent growth is aluminum extrusion, a process that has become foundational in industries ranging from automotive and aerospace to construction and consumer goods.

Behind this growth lies a demand for skilled labor. Aluminum extrusion operators have emerged as one of the most in-demand industrial roles, and for staffing firms like RSS Inc., connecting qualified workers with manufacturers has never been more important. As organizations seek to scale production and improve operational efficiency, the need for experienced extrusion operators is rising across the country.

What Does an Aluminum Extrusion Operator Do?

Aluminum extrusion operators are responsible for setting up, running, and maintaining machines that shape aluminum billets into precise profiles. These profiles are used to manufacture frames, rails, panels, and other structural or functional parts found in vehicles, buildings, and electronics.

Core responsibilities include:

- Setting up extrusion machines and loading aluminum billets

- Monitoring temperature, pressure, and feed rates

- Adjusting dies and tooling for different product specifications

- Inspecting finished extrusions for defects or inconsistencies

- Maintaining safety protocols and production efficiency

While the extrusion process is increasingly automated, skilled operators are still essential for interpreting production drawings, identifying issues in real-time, and ensuring high product quality.

The Employment Outlook: A Skilled Trade in High Demand

In today’s labor market, aluminum extrusion operators are not just machine handlers—they are problem solvers, technicians, and quality assurance specialists. As a result, demand for these professionals is steadily increasing across Canadian provinces.

Why Demand is Rising:

- Construction and Infrastructure Investment: Aluminum is widely used in windows, doors, roofing systems, and structural framing. As cities invest in green buildings and infrastructure renewal, extrusion jobs follow.

- Electric Vehicle Boom: EV manufacturers are increasingly turning to aluminum for lightweight frames and parts—fueling the need for precision extrusion.

- Sustainability Goals: Aluminum is recyclable and energy-efficient to process, making it a go-to material for eco-conscious industries.

- Skilled Trades Shortage: Canada is facing a labor gap in skilled manufacturing trades. Retirements and a lack of younger workers entering the sector are creating urgency for staffing firms and manufacturers alike.

Where Aluminum Extrusion Operators Are Employed

Operators are typically employed in:

- Metal fabrication plants

- Automotive part manufacturers

- Aerospace and defense contractors

- Construction supply manufacturers

- Third-party extrusion and fabrication service providers

These roles can be found across Canada, with particularly high concentrations in industrial regions of Ontario, Quebec, Alberta, and British Columbia.

Qualifications and Skills Employers Are Looking For

While some entry-level roles offer on-the-job training, most employers prefer candidates with technical knowledge or prior experience in manufacturing or extrusion environments.

Common qualifications include:

- High school diploma or equivalent

- Experience with CNC machines or metal fabrication

- Familiarity with extrusion presses, dies, and cutting tools

- Mechanical aptitude and troubleshooting ability

- Physical stamina and attention to detail

- Forklift certification (often an asset)

For employers, finding workers with these capabilities—and the willingness to learn and grow—can be a challenge. That’s where strategic staffing partners like RSS Inc. come into play.

How RSS Inc. Supports the Aluminum Extrusion Workforce

At RSS Inc., we understand that finding the right people for precision-based roles like extrusion operation takes more than a resume scan. It requires knowledge of both the technical aspects of the job and the culture of the workplace.

Our staffing process includes:

- Pre-screening for mechanical aptitude

- Verifying previous experience with manufacturing tools

- Matching skill levels to production environments

- Ensuring safety awareness and physical readiness

- Placing both temp-to-hire and full-time workers

We work closely with manufacturers to understand the scope of their operations—whether they’re seeking a single operator for a specialty run or staffing an entire production floor.

For candidates, we offer consistent access to industrial job opportunities, competitive pay rates, safety-first environments, and growth potential in skilled trades.

What Makes a Great Extrusion Operator?

Success in aluminum extrusion roles isn’t just about machine operation. It’s about adaptability, precision, and a team-oriented mindset. The best operators are those who:

- Take pride in producing defect-free parts

- Quickly adjust to new dies and product specifications

- Communicate clearly with quality control and supervisors

- Follow SOPs and continuously improve their work

- Stay updated on evolving safety standards and equipment

In a fast-paced production environment, reliability and consistency are just as valuable as technical skill.

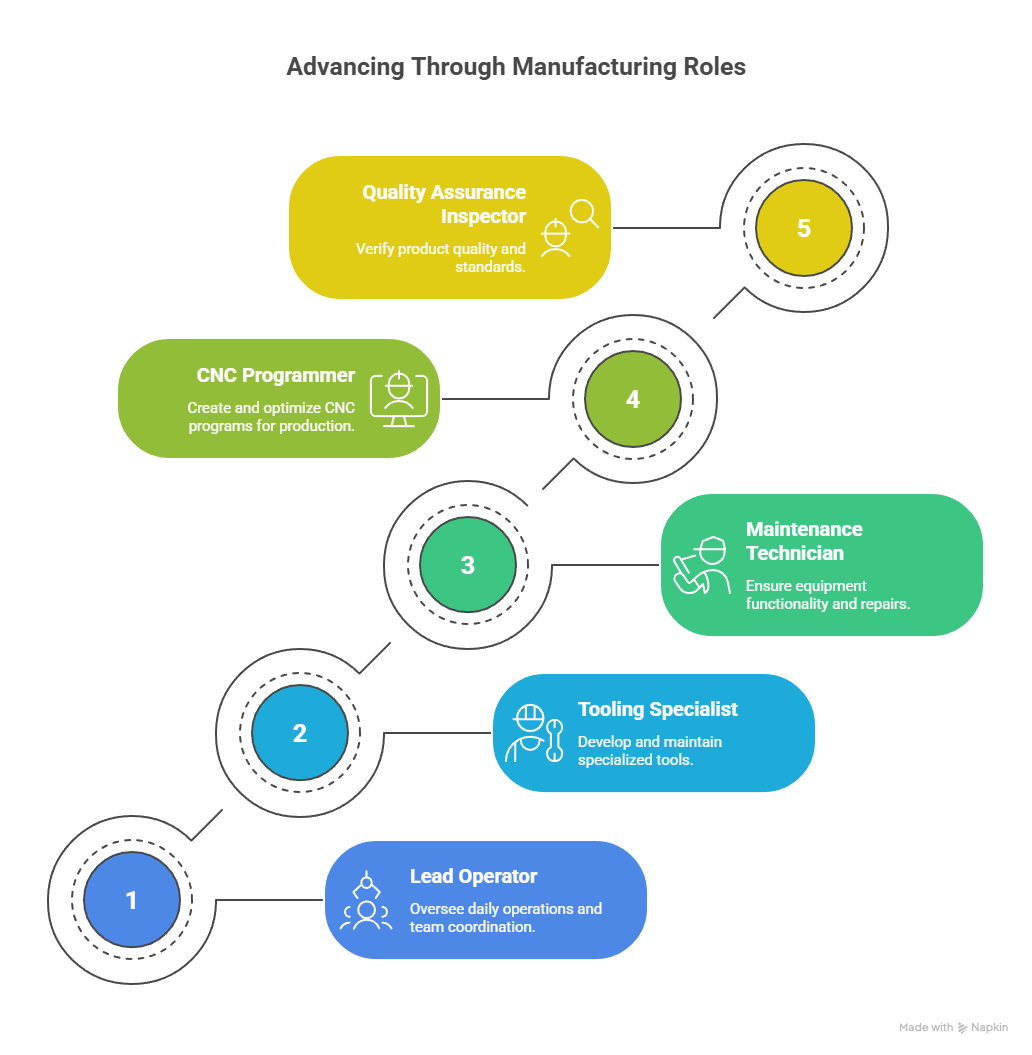

Upskilling and Career Pathways

Extrusion operation can serve as a long-term career or a launchpad to other roles in manufacturing. With the right training and experience, operators can advance into:

- Lead Operator or Shift Supervisor

- Tooling Specialist

- Maintenance Technician

- CNC Programmer

- Quality Assurance Inspector

Some organizations offer in-house training or tuition support for technical college programs. RSS Inc. helps workers identify these growth paths and connect with employers who invest in their teams.

Regional Employment Trends Across Canada

Aluminum extrusion operators are in demand across Canada, but hiring needs and job opportunities vary by province and industrial sector. Understanding these regional trends can help both employers and jobseekers make informed decisions.

Ontario

Ontario is home to a significant portion of Canada’s manufacturing base, especially in the Greater Toronto Area and Southern Ontario corridor. Aluminum extrusion is particularly vital in the automotive and aerospace supply chains. Companies in this region are frequently looking for skilled operators to keep up with production demands, especially in Mississauga, Brampton, Windsor, and Hamilton.

Quebec

In Quebec, the aluminum industry is bolstered by access to hydroelectric power and long-standing expertise in smelting and processing. Extrusion operators here often find roles in transportation, infrastructure, and construction-focused firms. Job opportunities are strong in Montréal, Laval, and Saguenay.

British Columbia

In BC, aluminum extrusion serves a growing green construction sector. The province’s focus on sustainability, combined with real estate development, makes aluminum a preferred material. Employers in the Lower Mainland and Vancouver Island often hire extrusion operators for architectural applications.

Alberta

Alberta’s manufacturing sector is tied to both the energy and construction industries. While not as concentrated in aluminum manufacturing as other provinces, extrusion operations do exist—particularly for infrastructure projects, oilfield equipment, and rail systems.

Training and Certification Pathways

To become an aluminum extrusion operator, formal education is not always required—but training and technical proficiency are essential. Here’s how workers can prepare for or advance in the role:

1. On-the-Job Training

Many employers offer in-house training programs for new hires. These programs cover:

- Machine setup and operation

- Basic maintenance

- Die changeovers

- Product quality inspection

- Workplace safety and PPE protocols

While this pathway is accessible, it can take several months before workers are ready to run extrusion presses independently.

2. Technical College Programs

Some Canadian colleges offer programs in:

- Industrial Manufacturing

- CNC Machining

- Mechanical Engineering Technology

- Metal Fabrication Techniques

These courses provide foundational knowledge in materials, mechanical systems, blueprint reading, and quality assurance. They’re often paired with co-op placements that give students real-world experience.

3. Certification

Certifications can strengthen a candidate’s resume and demonstrate competency to employers. While there’s no national standard specifically for extrusion, the following certifications are widely recognized:

- Forklift and crane operation certification

- WHMIS (Workplace Hazardous Materials Information System)

- First Aid / CPR

- Lean Manufacturing or Six Sigma training (for advanced roles)

RSS Inc. encourages all candidates to consider certification as part of their long-term career development plan.

Challenges in the Industry—and How Staffing Helps

1. High Turnover

Manufacturers often face high turnover in entry-level industrial roles. RSS pre-screens candidates for work ethic, career goals, and fit to reduce churn.

2. Skill Gaps

Not all applicants have experience with extrusion presses or aluminum handling. We help bridge this gap by recommending candidates who show strong learning potential—and by working with clients to establish training programs.

3. Workforce Shortages

With baby boomers retiring and fewer youth entering trades, the labor supply is tightening. Staffing agencies can expand the hiring pool by tapping into new networks, including immigrants, career changers, and retrained workers.

4. Urgent Staffing Needs

When demand spikes, such as during a new product launch or facility expansion, manufacturers need workers fast. RSS provides rapid response staffing backed by a qualified bench of industrial candidates.

Frequently Asked Questions (FAQ)

What shifts do aluminum extrusion operators typically work?

Extrusion facilities often run on multiple shifts—day, evening, and overnight—especially when operating high-volume production lines. Some facilities operate 24/7. Overtime and weekend shifts may be available depending on production cycles.

Is this a physically demanding job?

Yes. Operators are required to stand for extended periods, lift materials, operate heavy machinery, and work in high-temperature environments. Proper PPE is always provided, but candidates should be in good physical condition and comfortable in an industrial setting.

What is the average pay rate?

Wages vary depending on location, experience, and specialization, but most aluminum extrusion operators in Canada earn between $20 to $32 per hour. Lead operators or technicians with specialized skills can earn higher rates, especially in regions with a labor shortage.

What makes RSS Inc. different from other staffing firms?

RSS Inc. focuses on precision placements in industrial and skilled trades roles. We prioritize long-term success for both employers and workers, offering:

- Job matching based on technical fit

- Support with onboarding and safety training

- Regular feedback loops between clients and staff

- Commitment to fair wages and growth pathways

Let’s Shape the Future of Aluminum Extrusion

The aluminum extrusion industry continues to grow in size, sophistication, and strategic importance. For workers, it offers stable employment with room to grow. For employers, it presents opportunities to expand capacity and drive innovation—if the right people are on the production floor.

At RSS Inc., we’re proud to be part of that solution. We help companies across Canada connect with reliable, skilled aluminum extrusion operators who understand the value of safety, precision, and consistency. And we help jobseekers find opportunities that turn mechanical know-how into meaningful careers.

Looking to hire? Let our team source and screen qualified extrusion operators so you can focus on operations.

Looking to work? Reach out today to find aluminum extrusion operator openings near you, whether you’re experienced or ready to start a new path.

RSS Inc. — Staffing Canada’s Industrial Future.